About the author: Phil Taylor has over 35 years of experience in the field of manufacturing, sourcing and distributing binders, binding machines, binding supplies and print finishing equipment.

Document binding machines offer a convenient solution for individuals and organisations looking to create polished presentations, reports, manuals, and other materials. However, before investing in a document binding machine, several important factors warrant consideration to ensure you select the right one for your needs.

1. Different Document Binding Styles

Document binding machines come in various styles, each offering distinct advantages depending on the type of documents you need to bind. Common binding styles include:

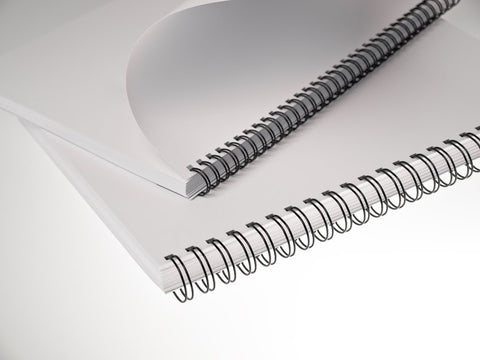

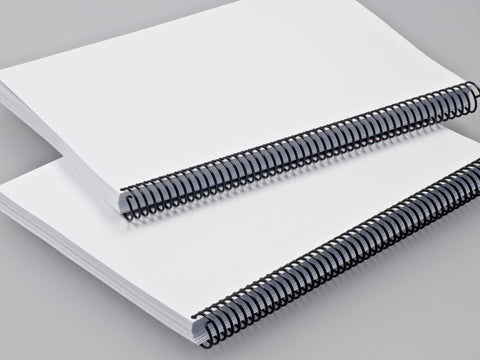

Wire Binding: Not to be confused with spiral binding, this style uses double-loop wires. Wire bound documents lie perfectly flat and sheets can be turned through a full 360 degrees (back to back) on the spine to save space when viewing. Wire bound documents cannot be edited once bound.

Comb Binding: Comb binding utilises plastic comb spines that thread through rectangular holes punched along the document's edge. This method offers easy editing and is suitable for documents of varying thicknesses.

Coil Binding: Also known as spiral binding, this method involves inserting a plastic or metal coil through pre-punched holes along the edge of the document. Spiral binding allows for 360-degree page rotation and is ideal for documents that need to lay flat when opened.

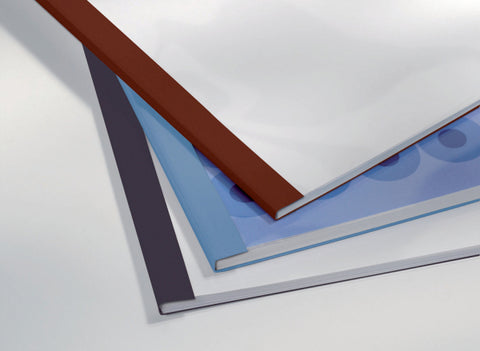

Thermal Binding: Thermal binding machines use heat to adhere adhesive-coated covers to the document's spine, creating a sleek and professional finish. Thermal binding is perfect for creating reports, presentations, and proposals.

Strip Binding: Strip Binding uses a 6mm wide plastic binding element. The spines come with a front and back that is linked by the prongs on the front piece. Strip binding systems trim any excess prong on the front spine before heat welding the front of the spine to the rear for a neat and totally tamper-proof finish, making this solution very popular for legal and accountancy documents.

2. Wire Binding vs. Comb Binding Machines

The most popular forms of binding are wire and comb, so one of the key decisions when choosing a document binding machine is whether to opt for a wire binding or comb binding machine. While both serve the same purpose of securely binding documents, they differ in their mechanism and features.

Wire Binding Machines: Wire binding machines are compatible with binding wires, which offer flexibility and durability. They are suitable for binding documents of varying thicknesses and sizes. Most people agree that wire binding offers a more professional and aesthetically pleasing finish when compared to plastic comb binding. Wire bound documents lie perfectly flat and sheets can be turned through a full 360 degrees on the spine. In addition, pages are bound so securely that they won't fall out and documents maintain their neat appearance for the lifetime of the information. Wire bound documents cannot be edited once bound. The Renz WIRE GO 3:1 Heavy Duty Manual Wire Binding Machine is an excellent option for those seeking a reliable wire binding solution.

Comb Binding Machines: Comb binding machines use plastic comb spines, which are available in various colours and sizes. The spines are inexpensive, easy to use and offer the flexibility to add or remove pages as needed. Plastic comb binding is the most common form of binding found in offices and at home and there is a wide selection of machines available to cover many applications and document volumes or document sizes. Consider the Fellowes Galaxy 500 Office Manual Comb Binding Machine for a good quality, value-for-money comb binding experience.

3. Binding Volumes

Before ordering a binding machine, it’s very important to take stock of the volume you expect to bind on a regular basis. For example, how many items you might typically bind in a day, or week, or if less frequently than this, when you process a batch of documents.

Essentially, the higher the price of a binding machine within each binding style, the more robust it will be and the more adequate it will prove for processing higher volumes. The overall number of sheets to be punched is also important, so if you bind 10 documents per week of on average 200 sheets each compared to 10 documents of only 50 sheets per week, the former will constitute higher volumes than the latter and this should be taken into account when selecting a suitable unit.

Consistently the highest quality and most robust units are those manufactured by Renz. These machines are made wholly in Germany and largely from metal components making them very robust and very durable. A Renz binding machine can last many years if operated correctly. The overall quality of the binding and, for example, the precision of the holes punched by a Renz machine is also superior to other manufacturers, particularly when working close to the maximum punch capacity.

4. Maintenance Tips for Binding Machines

Proper maintenance is essential to ensure the longevity and optimal performance of your binding machine. Here are some maintenance tips to keep in mind:

Regular Cleaning: Remove dust, debris, and paper remnants from the machine's components using a soft brush or cloth.

Lubrication: Apply lubricant to moving parts according to the manufacturer's instructions to prevent friction and ensure smooth operation.

Inspection: Regularly inspect the machine for signs of wear and tear, and promptly address any issues to prevent further damage.

Chip/waste tray: If there is a chip tray present (this collects the small, punched waste pieces from the paper that create the holes for inserting the appropriate spine), it is essential to ensure this is emptied regularly and before becoming overfull as otherwise serious damage can be caused to the unit.

5. Versatility of Binding Machines

Document binding machines offer versatility beyond traditional office documents. With the right machine, you can create:

Presentations and Reports

Training Manuals

Proposals and Contracts

Marketing Collateral

Cookbooks and Recipe Books

You can also use a binding machine for the hobby or professional creation of scrapbooks, photobooks and customised or designer notebooks.

Whether you opt for a spiral, comb, or thermal binding machine, the possibilities are endless.

6. Understanding Binding Wire Ratios

When selecting binding wires for your document binding machine, understanding wire ratios is essential. The ratio refers to the number of holes punched per inch along the document's edge. Common ratios include 3:1 and 2:1, each suitable for different thicknesses of documents.

3:1 Binding Wires: Ideal for thinner documents, the 3:1 ratio means there are three holes per inch along the document's edge (or 34 holes in total along the long side of an A4 sheet of paper – hence 34 loop), providing a secure bind without overcrowding the spine.

2:1 Binding Wires: With two holes per inch (or 23 holes in total along the long side of an A4 sheet of paper – hence 23 loop), 2:1 binding wires are designed for thicker documents, offering enhanced durability and stability.

In conclusion, investing in a document binding machine is a significant decision that requires careful consideration of your specific needs and preferences. By understanding the different binding styles, maintenance requirements, versatility, and wire ratios, you can make an informed choice that enhances your document presentation capabilities.