About the author: Phil Taylor has over 35 years of experience in the field of manufacturing, sourcing and distributing binders, binding machines, binding supplies and print finishing equipment.

In the realm of document binding, thermal binding stands out as a reliable and efficient method to create professional-looking booklets, reports, and presentations. Its simplicity, coupled with its ability to produce high-quality results, makes it a preferred choice for many offices, businesses, and educational institutions.

What is Thermal Binding?

Thermal binding is a process of securing loose pages together by using heat to melt adhesive material in a thermal binding cover. This adhesive, typically in the form of resin or glue, binds the document securely, creating a polished and professional finish. Thermal binding covers usually consist of a clear acetate front and a colour-coordinated card-based spine and rear cover. Hardback thermal binding covers are also available for use with appropriate machines only, such as the Opus Duo 500 Heavy Duty Thermal Binding Machine.

Is Thermal Binding Good?

Absolutely. Thermal binding offers numerous advantages. Firstly, it provides a clean and sleek appearance to documents, enhancing their professional presentation. Additionally, thermal binding is quick and easy, requiring minimal setup and no punching or threading of materials. It's also highly customisable, accommodating documents of various sizes and thicknesses. Furthermore, thermal-bound documents lay flat when opened, offering convenience and readability and are ideal for posting due to the low profile of the binding spine compared to wire or comb binding, for example.

How Do You Thermal Bind a Document?

Thermal binding is a straightforward process that can be completed in a few simple steps:

Prepare Your Document: Organise the pages of your document in the desired order.

Choose the Right Cover: Select a thermal binding cover that matches the size and thickness of your document.

Insert the Pages: Place the prepared document into the thermal binding cover, ensuring that all pages are aligned properly.

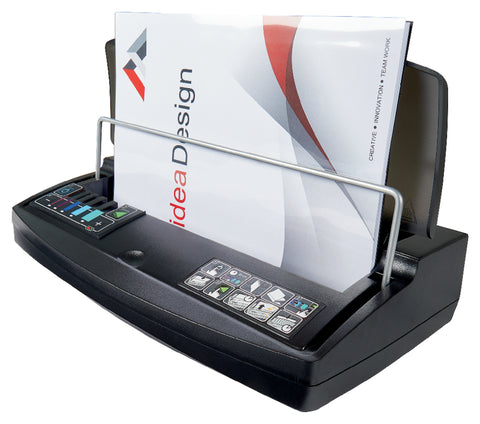

Heat the Binding Cover: Place the covered document into a thermal binding machine. Activate the machine to apply heat, which will melt the adhesive and bind the pages together. The unit automatically informs you when the binding cycle is complete.

Cool and Remove: Allow the bound document to cool for a few minutes in the cooling rack provided before handling. Once cooled, the document is ready for use.

Below is a useful video from GBC demonstrating the thermal binding process. The procedure is not identical for all makes and models, but the principle is the same with a similar process across all machines.

Thermal Binding vs. Spiral Binding: What's the Difference?

While both thermal binding and spiral binding are popular methods for securing documents, they differ in several key aspects:

Appearance: Thermal binding produces a sleek and professional-looking finish, whereas spiral binding creates a more functional but less refined appearance.

Durability: Thermal binding offers greater durability, as the adhesive creates a strong bond that holds the pages securely in place. Spiral binding relies on a plastic coil, which may become loose or damaged over time.

Lay-flat Capability: Thermal-bound documents lay flat when opened, providing convenience and ease of use, but they cannot be turned through a full 360 degrees (back to back) on the spine as this will eventually damage the binding.

How Long Does Thermal Binding Take?

The time required for thermal binding varies depending on factors such as the size and thickness of the document, as well as the specific thermal binding machine being used. Generally, the process takes only 1½ - 2 minutes and as most thermal binding machines allow the binding of multiple documents at once up to the stated maximum sheet capacity, this makes it a quick and efficient option for binding documents on the go.

The Fellowes Helios 60 Thermal Binding Machine can bind up to 600 sheets in one batch, for example.

In conclusion, thermal binding is a versatile and effective method for creating professional-looking documents. Its simplicity, speed, and high-quality results make it a valuable tool for offices, businesses, and educational institutions alike. Whether you're binding reports, presentations, or manuals, thermal binding delivers outstanding results every time.