About the author: Phil Taylor has over 35 years of experience in the field of manufacturing, sourcing and distributing binders, binding machines, binding supplies and print finishing equipment.

In the realm of document binding, comb binding stands out as a versatile and cost-effective method. Whether you're organising reports, creating presentations, or compiling manuals, comb binding offers a simple yet professional solution. In this comprehensive guide, we'll delve into the world of comb binding, exploring its different formats, applications, and providing valuable tips for success.

What is Comb Binding?

At its core, comb binding involves punching holes along the edge of a stack of papers and securing them together using a plastic comb. This process creates a durable and tidy-bound document that allows pages to be easily turned and lays flat for convenient reading or photocopying.

What Does a Comb Binder Do?

A comb binder is used to bind documents, reports, manuals and presentations, etc. using plastic comb spines. The comb binder punches holes along the edge of the sheets to be bound which match the prongs on a plastic binding comb. The machine also holds the plastic spine open while sheets and binding covers are loaded, before closing the spine to complete the comb binding process.

How Many Pages Can You Comb Bind?

Comb binding machines can bind up to 450 sheets of standard 80gsm printer paper or a document 51mm thick using plastic combs. Plastic combs come in various diameters up to a maximum of 51mm to match the thickness of the document being bound.

Does Comb Binding Lay Flat?

Yes, plastic comb bound documents lay flat, but sheets cannot be turned through a full 360 degrees (back to back) on the spine to take up less room when being viewed. Plastic comb documents can also be re-opened to edit documents by adding or removing sheets.

What Are the Advantages of Comb Binding?

Plastic comb binding is one of the most popular forms of binding. Plastic combs are not only durable, but they can be re-used. Comb binding is an inexpensive and very economical way to bind documents as the machines and supplies are available at relatively low prices. Documents can also be edited as it is possible to re-open a binding comb using the same machine and add, remove or update sheets.

What Are the Disadvantages of Comb Binding?

Most people would agree comb binding’s main disadvantage is the aesthetic. It could be said that it lacks the professional image of, for example, a wire bound or thermal bound document. Due to the nature of the binding spine, documents made with comb binding can also be a little bulkier which can be an issue for postage as the binding comb can easily become distorted or damaged when sent through the mail.

In addition, one of the benefits of comb binding is that documents are editable, but this becomes a disadvantage for documents that need security such as contracts and other legal papers.

Different Comb Binding Formats

Comb binding machines come in various formats, catering to different needs and volumes of binding. Here are some popular formats:

Manual Comb Binding Machines: Ideal for small to medium-scale binding tasks, manual comb binding machines like the Fellowes Lyra 3-In-1 Office Manual Comb Binding Machine offer simplicity and affordability. They require manual operation, including punching the holes and manually inserting the comb, making them suitable for occasional users. See our manual comb binding machines here.

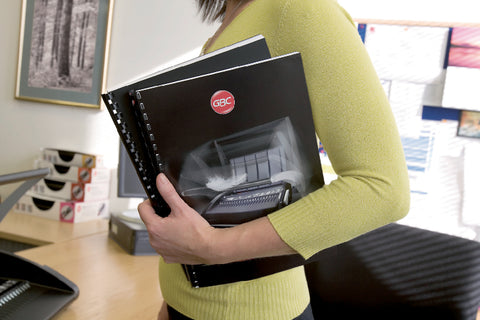

Electric Comb Binding Machines: For higher volumes of binding, electric comb binding machines like the GBC CombBind C450E Office Electric Comb Binding Machine provide efficiency and speed. With electric hole punching and features like document auto-centring, these machines streamline the binding process, saving time and effort. See our electric comb binding machines here.

Heavy-Duty Comb Binding Machines: When faced with large-scale binding projects, or regular high volumes, heavy-duty comb binding machines such as the Fellowes Orion Heavy Duty Manual Comb Binding Machine offer durability and reliability. Built to withstand frequent use and handle thicker stacks of paper, these machines are the go-to choice for busy offices, reprographic departments or print shops.

Applications of Comb Binding

Comb binding finds applications across various industries and settings:

Business Reports and Proposals: Present your business reports and proposals in a professional manner with comb binding. It adds a polished finish and makes documents easy to navigate.

Educational Materials: Teachers and students can benefit from comb binding for creating study guides, course materials, and presentations. It facilitates organisation and enhances readability.

Training Manuals: Ensure consistency and durability in your training manuals by comb binding them. Whether for employee onboarding or customer education, comb-bound manuals offer a professional touch.

Marketing Collateral: From product catalogues to promotional materials, comb binding adds a professional edge to your marketing collateral. It allows for easy customisation and updating of content.

Hints and Tips for Successful Comb Binding

To achieve optimal results with comb binding, consider the following tips:

Choose the Right Comb Size: Select a comb size that accommodates the thickness of your document without leaving too much excess space. This ensures a snug fit and prevents pages from shifting.

Invest in Quality Binding Supplies: Opt for high-quality plastic combs and covers to enhance the durability and appearance of your bound documents. Quality supplies contribute to a professional finish.

Prep Your Documents Properly: Before binding, ensure that your documents are neatly stacked and aligned. Remove any torn or damaged pages to prevent issues during the binding process.

Experiment with Cover Options: Consider using clear or frosted covers for the front and back of your bound documents to provide added protection and a polished look.

Practice Proper Punching Technique: When punching holes, apply consistent pressure and ensure that the paper is properly aligned within the punching guide. This helps prevent misaligned holes and ensures a clean finish.

Utilise Binding Machine Features: Familiarise yourself with the features of your binding machine, whether manual or electric. Adjust settings as needed for different paper sizes and thicknesses to achieve optimal results.

Below is a great video from Fellowes on the operation of a comb binding machine.

Conclusion

Comb binding offers a cost-effective and efficient solution for creating professional-looking bound documents. Whether you're a small business owner, educator, or office manager, using comb binding can streamline your document organisation and presentation efforts. By understanding the different formats, applications, and implementing the tips provided, you can harness the power of comb binding to elevate your document binding experience.

Ready to take your document binding to the next level? Explore our range of comb binding machines and supplies to get started today!